News

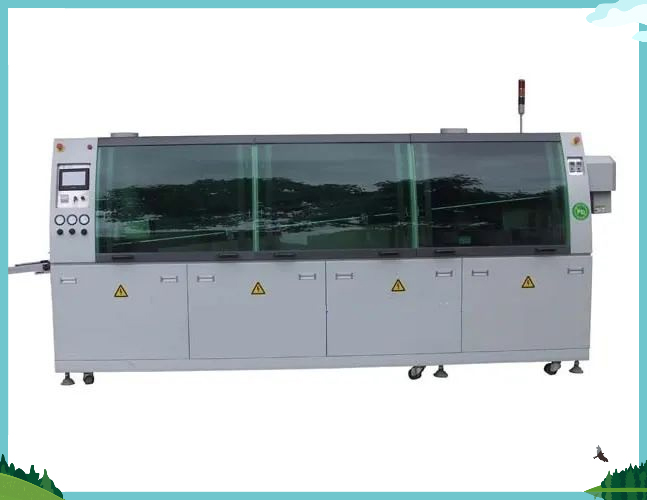

Routine maintenance and care of wave soldering

Wave soldering operators should maintain and service the machine from time to time to ensure personnel and equipment safety, normal operation and product quality, reduce equipment failure and avoid accidents.

So the operator must do the following:

1.The equipment must often keep the hot air, cooling, transmission, wave and other motor housing clean for heat dissipation.

2.Regularly check the tin furnace, pre-heater in the heater connection, such as found loose, poor contact, insulation aging and other phenomena should be tightened, cleaned, replaced; should always check whether the equipment grounding is good.3.The opening and closing of the main power switch in case of a situation should be done only after stopping the high current loads such as tin furnace, preheating and wave crest.

4.When the wave motor is not rotating, manual speed control is prohibited to prevent damage to the speed control mechanism; melting solder and adding high-temperature liquid solder to the furnace process, you need to wear the necessary protective equipment to prevent burns.5.Each transmission part should be kept well lubricated, in addition to the angle adjustment mechanism can be used for ordinary grease, the rest should be lubricated with high temperature grease.

6.Regularly check the lubrication and operation of the wave motor to ensure its normal operation; clean the nozzle of the tin furnace once a week to avoid blocking the nozzle due to debris and affecting the smoothness of the wave.