In-line Dispensing Machine Solutions for the Home Appliance Industry

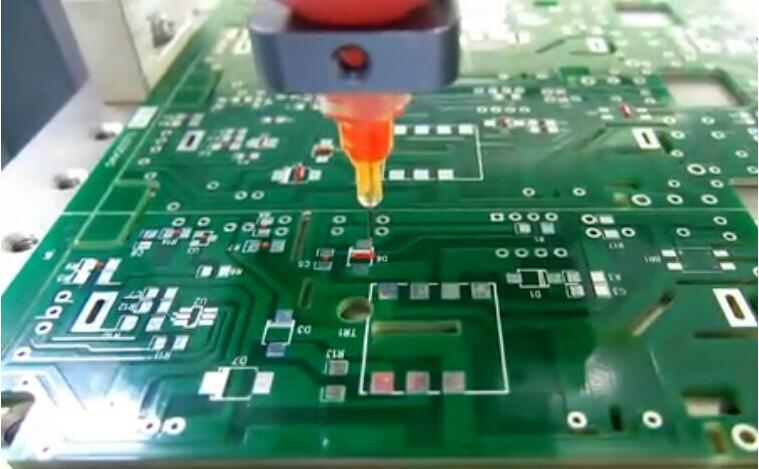

In-line dispensing machine is a kind of dispensing equipment used to finish the encapsulation work in the process products. SINGSUN ELECTRONIC SCIENCE & TECH CO., LTD has launched an in-line dispensing solution for the home appliance industry, which can realize the sealing of IC chips and other components on the remote control PCB board and is compatible with the dispensing of photoelectric switches.

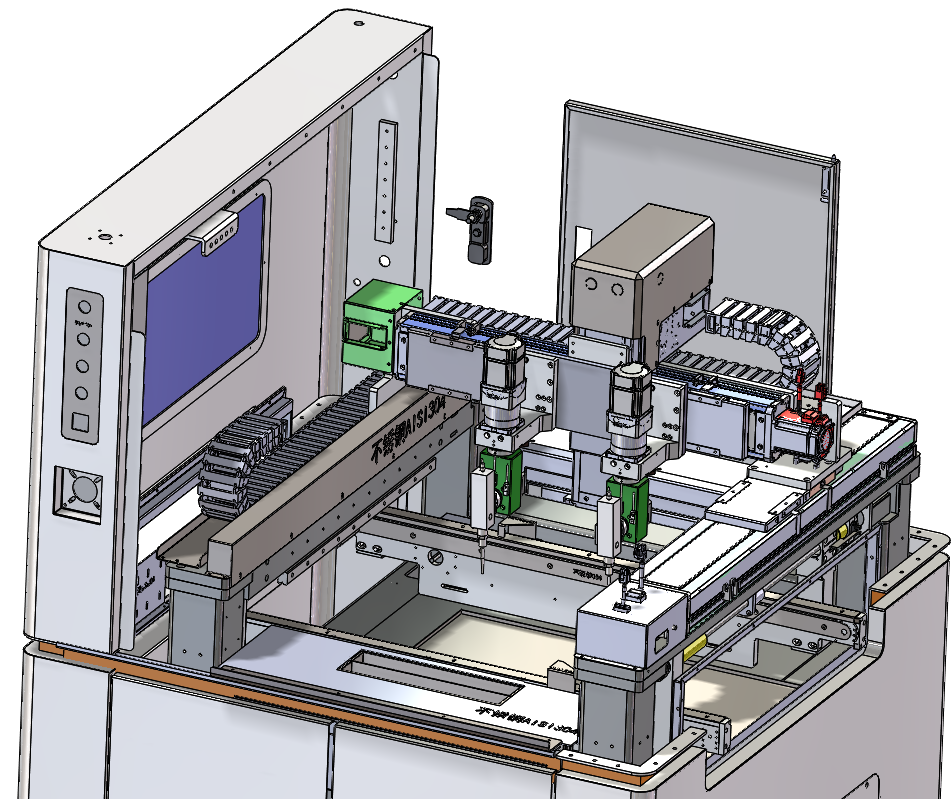

Online dispensing machine is a kind of dispensing equipment that can be produced on the assembly line, in the sense that the real fully active dispensing machine, can achieve active loading and unloading, simply do not need to use to manual operation, this is the non-stop work of the online dispensing machine, with good dispensing technology, applied to the industry dispensing effect will be very high. Online dispensing machine is used to complete the process products in the encapsulation of a dispensing equipment, with the rapid development of the manufacturing industry, the requirements for dispensing equipment is also increasingly high, the general dispensing machine can only complete the general dispensing mission, in some need for batch production of the production process, or the use of online dispensing machine is good, whether in the dispensing quality, or production advantages, online dispensing equipment, but also the assembly line dispensing machine. SINGSUN ELECTRONIC SCIENCE & TECH CO., LTD has introduced a new in-line dispensing solution for the home appliance industry. Program Objective: Realizes the application of sealant to IC chips and other components on remote control PCB boards, and is compatible with the dispensing of photoelectric switches. Basic functions of the equipment : 1.Equipment with visual positioning function 2.Detection function 3.Rubber valve with suck-back function 4.Front and rear can be equipped with the upper and lower trigger operation 5.Manpower allocation: 0 people Equipment parameters Voltage: 220V AC, 50Hz Operation control circuit: DC24V Compressed air: 0.4~0.6MPa 1.The width of the conveying line can be adjusted according to different materials. 2.After blocking the material, the jacking mechanism can jack up the plate to achieve complete positioning. 3.Coating is done by XYZ fit. 4.Within a certain stroke, the valve can be added to complete the coating of multiple pieced boards at one time.